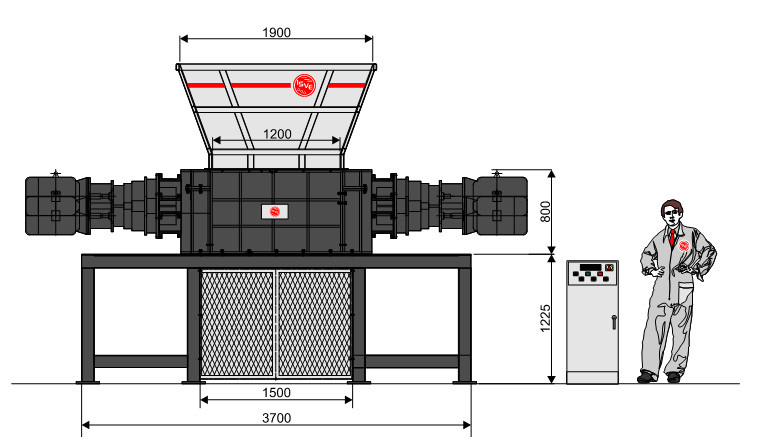

The 120/130S-MAX 4-shafts shredder is an heavy machine with a 1.200×1.300 mm load door and it is equipped with special conveyor disks besides the cutters. This model is provided with 4 gearmotors with a total power of 81 kW with high force of cut.

The “MAX” series has been expressly studied for hard works for the recycling field.

Main features:

- Total installed horsepower: 91 kW/104 kW

- drive: gears

- n. Cutter shafts: 2

- n. Hardened cutters: 30 with thickness of 40 mm (available thicknesses also of 50 and 70mm

- n. Conveyor shafts: 2

- n. conveyor disks: 30 with 4 beak and thickness of 40 mm

- n. average cutter revs./min.: 18

- production: 3-6 t/hour

- accessories: hydraulic gear case for interchangeable screen

- safety precautions: emergency stop, hopper closed contact

- weight: about 10 t.

- manufactured to EC standards.

Explanatory notes:

Heavy machine for hard works. Thanks to the the great power of cut, this machine is suitable to be used as single pre-crusher for voluminous materials or as secondary shredder to control the size by using an evacuating screen

Recommended for shredding track and car bumpers, polypropylene tanks, bulky scraps, tyres, leather, rags, metal cans, hospital and ship scraps, etc

Characteristics of the shredder:

- Very thick welded sheet steel support;

- Support for barrel roller bearings with sealing system against dust and liquids;

- High-resistence shafts;

- No. 30 special anti-wear steel cutters with thickness of 40 mm and 2 “beaks”;

- No. 30 conveyor disks with thickness of 40 mm and 4 “beaks” to facilitate gripping of bulky objects

- No.2 epicyclic reduction gears for cutter shafts driving.

- No.2 epicyclic reduction gears for conveyor disks shafts driving.

- No.2 30 or 37 kW “Siemens” motors for cutter shafts driving;

- No.2 15 kW “Siemens” motors for conveyor disks shafts driving;

- 1200×1300 mm cutting chamber;

- Interchangeable screen with hydraulic servocontrol to facilitate maintenance and replacing.

- Reinforced welded sheet metal hopper prepared with loading by “spider”.

- Base made in electrowelded steel tubulars fitted with protection nets and security micro;

Characteristics of control system:

- Electric switchboard complying with CEE standards, equipped with torque limiting device which inverts the direction of the pusher drawer if the work load of the machine exceeds the set value;

- S7-1200 SIEMENS PLC to control all the plant peripheral units;

- SIMATIC SIEMENS touch screen to adjust all the parameters of the machine;

- Software prepared to control the loading system, the grinder and the suction plant.

- Emergency control functions for stopping the system;

- ISVE MAINTENACE PROGRAM: it signals the ordinary maintenance interventions at their expiry date.

- The production of shredder material varies depending on the type of piece to be ground and the size of the ground items required. On an average it is possible to produce between 3-6 t per hour

- Made to CE standards.