Operation and machine description of double-shafts shredders

Heavy 2- shafts shredders with loading hoppers, equipped with high quality cutters with low rotation speed for a lower energy consumption and noise reduction.

Grinding group designed for a maximum productivity and operation, with anti-wear enhanced thickness steel tools. If subject to excessive loading, the machine automatically performs a temporary inversion of the blades movement to avoid overloading. Electronically controlled by PLC. A wide range of accessories for loading and unloading operations.

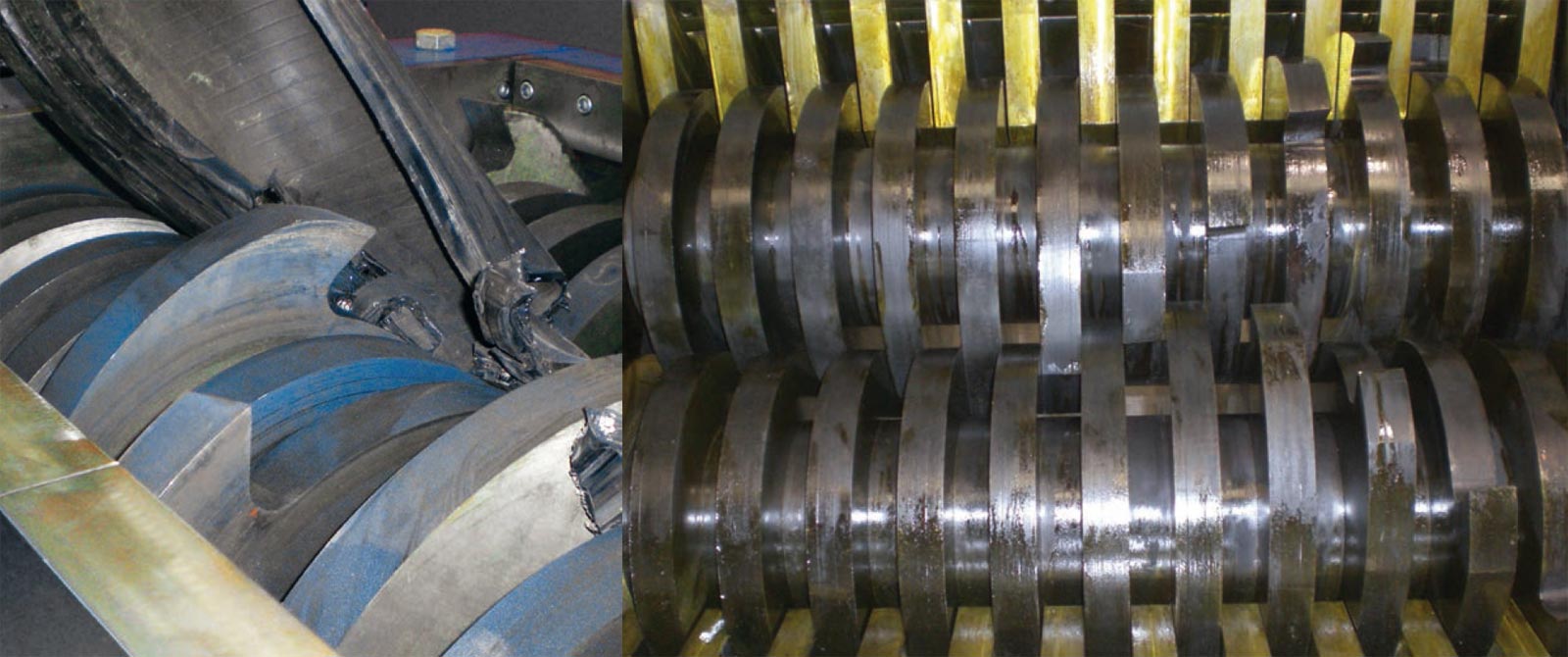

The machine is composed by a two-shafts shredder with rotary blades and specer combs.

Once the material is into the hopper and the machine is ON, the shredder catches the material and begins to cut it grossly.

Thanks to the high cutting torque and the different conformation of the cutters group it’s possible to shred pieces made of different materials.

The process is automatically regulated by a PLC that can be programmed through the display placed on the electric board.

| FROM | TO | |

| Temperate milling cutters | 20 | 30 |

| Spacing combs | 20 | 30 |

| Input width mm | 800×690 | 1.200×690 |

| Power KW | 30 | 44 |

| Weight Kg | 4.700 | 7.300 |

| Production Kg/hour | 900/1.500 | 2.500/3.000 |

| Safety equipment: emergency stop, shutdown button, electronic control. | ||

SHREDDING GROUP

Loading unit:

Hopper (1).

Shredding unit:

2 shafts with sharp elements constituted by sharp-corners disks (3) provided with hooks (2)

Every hook has the task to hook the product and drive-it by the action of the two counter-rotating shafts.

The spacer combs (4) keep the tools clean and make material unloading easy.

Motor drive:

No. 2 Alternated current asynchronous electric motor. Drive by epicyclic reduction gears.

Connexion between cutter-holder shafts and conveyor with oil bath gears.

Security device:

It temporarily reverses cutters movement preventing structural overloading or machine breaking in case of excessive quantities to shred or material that cannot be shred. This device allows an excellent adjusting of grinding group to not penalize productivity and regular working.

SERIE “S” ISVE: WATCH THE DIFFERENCE!!!

SIEMENS ENGINES

To warrant the best quality to our products all our shredders are equipped with SIEMENS motors.

HEAVY STRUCTURE

The frame and structure of our shredders are made of high-thickness sheets and tubular. This gives big resistance against the most demanding jobs.

TOUCH PANEL

The new control unit of our shredders is made up of the S7-1200 SIEMENS PLC. To facilitate the programming and running of the shredders and its associated peripherals, the user can use an easy touch panel. The system has been designed to be of quick comprehension and easy to use. With a single gesture it is possible to activate loading conveyer belts, refiningg and suction systems. The control can be centralized and automated.

ISVE MAINTENANCE PROGRAM

The new control system allows to signal to the operator the ordinary maintenance intervention at its expiry date.

ISVE SERVER CONNECT

with an additional form, every machine can be connected on-line through the office net or with an UMTS card (against covering verification). With this system, the grinder functioning is monitorized directly from the mother-house. Moreover, software uploads and remote functioning parameters regulation are available.

CAMERA INSIDE

All our shredders are equipped with a camera placed near the loading hopper. The operator could easily check the correct running of the machine through the electrical board.