The MS 22-60 single-shaft shredder is particularly suitable to shred high-consisting wastes.

A hydraulic control unit allows driving the pusher drawer. Thus, the product to be grinded is pushed towards a tools-holder rotor causing its crushing.

Thanks to a screen it is possible to select the final dimension of the shredder material.

Main features:

- Power installed on the rotor: 18,5 kW (25 HP)

- Power of the hydraulic control unit: 2,2 kW (HP 3)

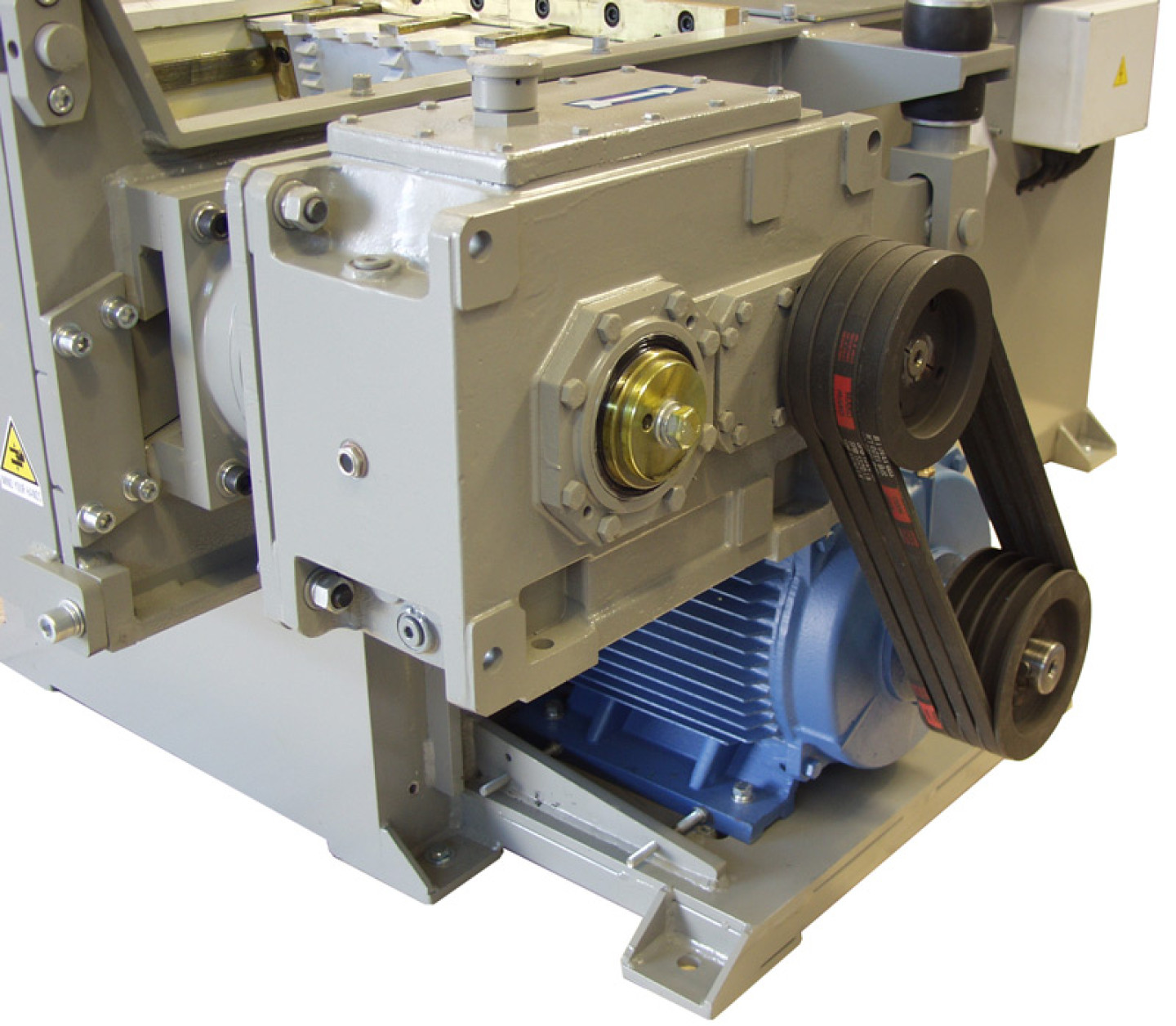

- Drive: by belts

- Number of rotors: 1

- Rotor diameter: 220 mm

- Rotor length: 600 mm

- Number of reversible tools: 27

- N° of usable tools sides: 4

- Average number of rotor revolutions per min: 85

- Weight: 1.800 kg

- Production: 200-400 kg/h

- Safety devices: emergency stop, drawer reversal system.

Explanatory notes:

Small-medium sized multipurpose machine suitable for shredding wide range of waste materials.

It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood, high thickness plastic material, paper, confidential documents, extruded sheets, small tires, etc.

Characteristics of the shredder:

- Strong welded steel framework;

- Support for barrel roller bearings with sealing system against dust and liquids;

- High thickness rotor with diameter of 220 mm and length of 600 mm. It is equipped with 23 tools-holder plates and 27 high alloyed anti-wear tools usable 4 times;

- No. 2 adjustable counter-blades (upper and lower) made in very alloyed anti-wear steel;

- Pusher drawer with hydraulic driving with 500 mm of usable run;

- Hydraulic unit;

- Pulleys and belts drive system to avoid damaging mechanical due to rotor vibrations;

- No. 1 multi-voltage and multi-frequency motor of 18,5 KW of primary national company with PREMIUM efficiency class (IE3) and no. 1 motor of 2,2 KW for the hydraulic unit;

- 600 X 700 mm cutting chamber;

- Welded sheet metal hopper for top loading;

- Interchangeable screen establishing the size of the shredded material;

- Discharge system: to be defined.

Characteristics of control system:

- Electric switchboard complying with EEC standards, equipped with torque limiting device which inverts the direction of the rotor if the work load of the machine exceeds the set value;

- Main internal board (LOGO SIEMENS) for the control of all the plant peripheral units;

- Emergency control functions for stopping the system;

- Made to CE standards.

Accessories

- Interchangeable screen establishing the size of the shredded material (diam. 14-16-20-25-30-35 mm).

- Drawer connectable to a suction system with outlet connection diameter 160 mm.

- Collection drawer for shredded material, equipped with 4 swivel wheels, plexiglass inspection window, fixing knobs and safety micro.

- Upper hopper closure with side window equipped with rubber bands to avoid material leakage during grinding.

- Rotor cooling system.

SPECIFIC ACCESSORIES FOR ELECTRIC CABLE MILLING:

- Rotor protection plate (prevents rotor overloads when loading hank materials).

- Shredder stop software in case of overloaded separation system/refiner mill.