Isve granulators GR series

Plated granulators to refine non-ferrous materials: plastic, cardboard, wood, confidential paper documents, etc.

For a good price/performance ratio, these mills are used for the grinding and refining of thick materials requiring an enhanced cutting.

All the models are equipped with a rotating and fixed blades wearing offsetting, a double wheel and programming for water cooling.

They can be additionally equipped with a full rotor or with a continuous blade open rotor.

Interchangeable hoppers, loading conveyor belts, dusting and big-bag packing systems are included in the accessories upon request range.

| FROM | TO | |

| Rotor power KW | 7,5 | 30 |

| Rotor length mm | 360 | 1.000 |

| Rotating blades | 18 | 33 |

| Fixed blades | 2 | 2 |

| Weight Kg | 750 | 3.000 |

| Production Kg/hour | 80/150 | 1.000 |

| Safety equipment: emergency stop, shutdown button, electronic control. | ||

Cumberland core!

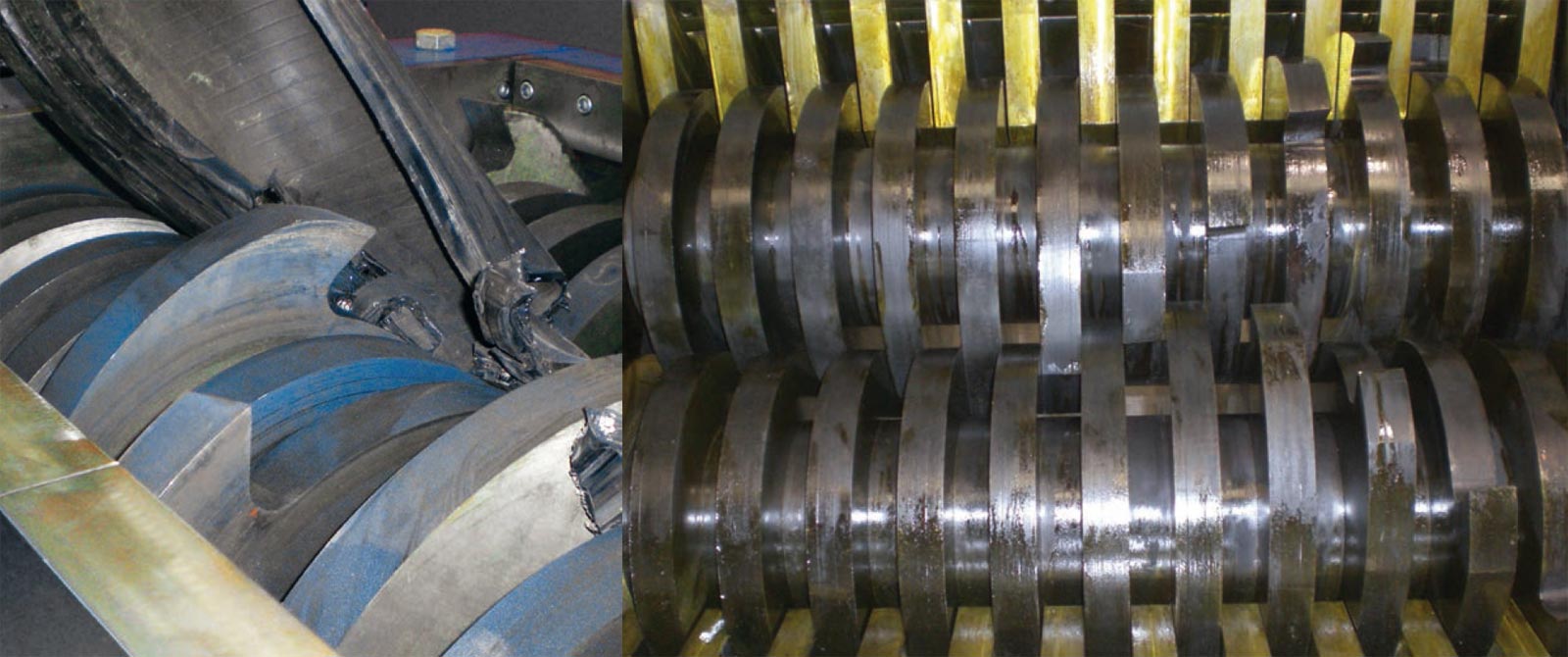

Cumberland inside

ISVE uses cutting chambers made from CUMBERLAND, a worldwide known brand for produxtion of granulators and englobed in the Americas multinational company, ACS.

ISVE grinders have been designed to meet different needs of grinding of plastic material.

Some exclusive features that are listed below characterize these grinders:

System EASYACCES

The traditional granulators have the rotor turning clockwise, so towards to the side of the engine of the machine. This involves the positioning of fixed counter-blades often rather uncomfortable to reach.

CUMBERLAND ® grinders have been designed to rotate counterclockwise, namely towards outside of the granulator.

This allowed obtaining more space before the cutting chamber favouring the action of “taking” of voluminous elements. The regulation of fixed counter-blades is also very simple.

ROTOR

The rotor is places sideways and it is integral with two rotating discs to avoid that filamentary materials twine round the blades-holder axle. This system, thanks to the particular flights inside the flange, ensures the cooling of lateral walls and bearings. One pivot key allows the blocking of the rotor in comfortable positions to change rotary blades.

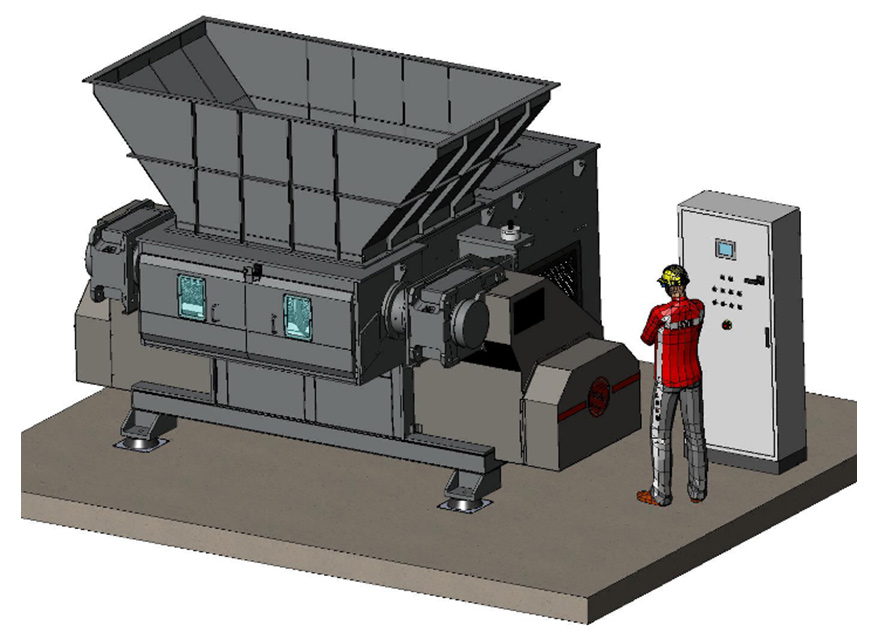

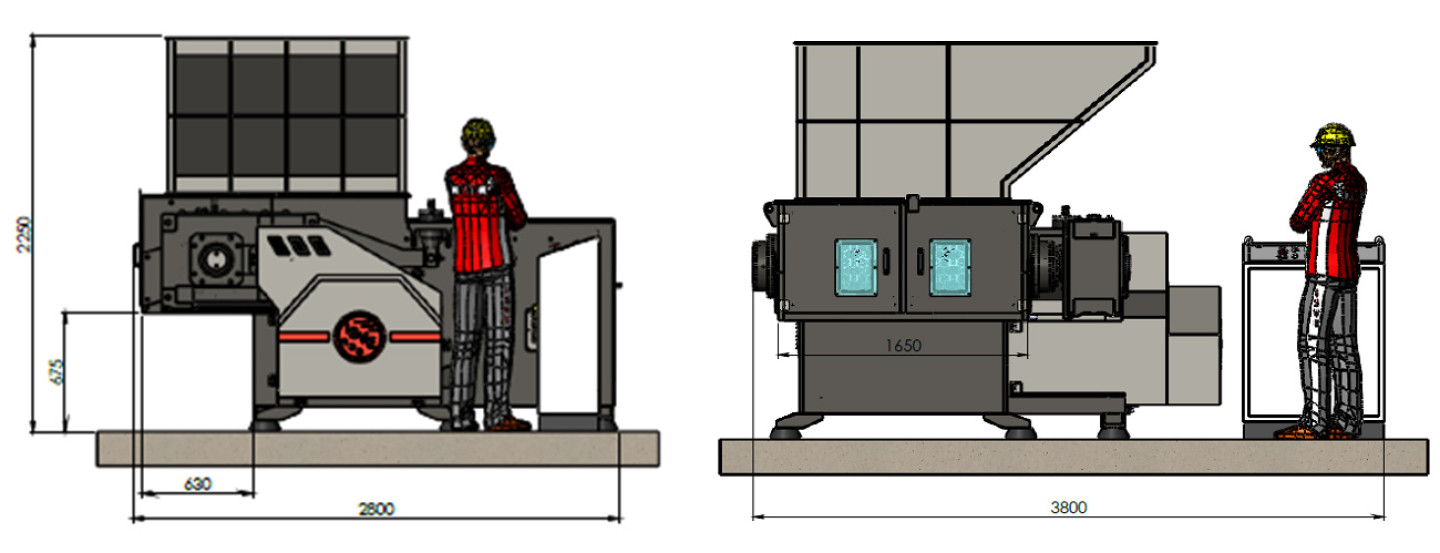

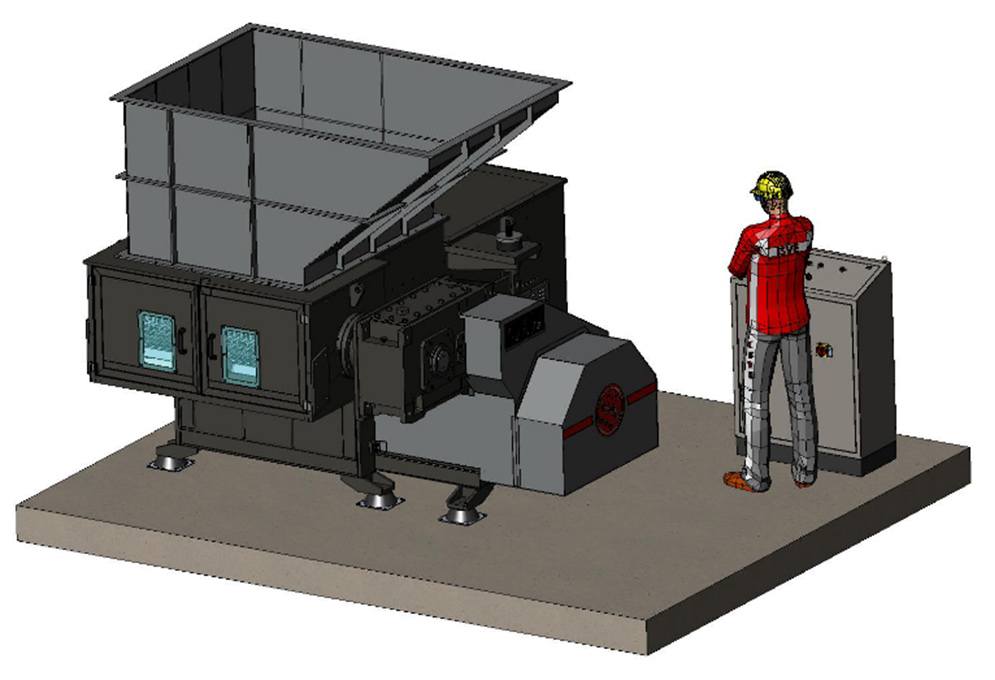

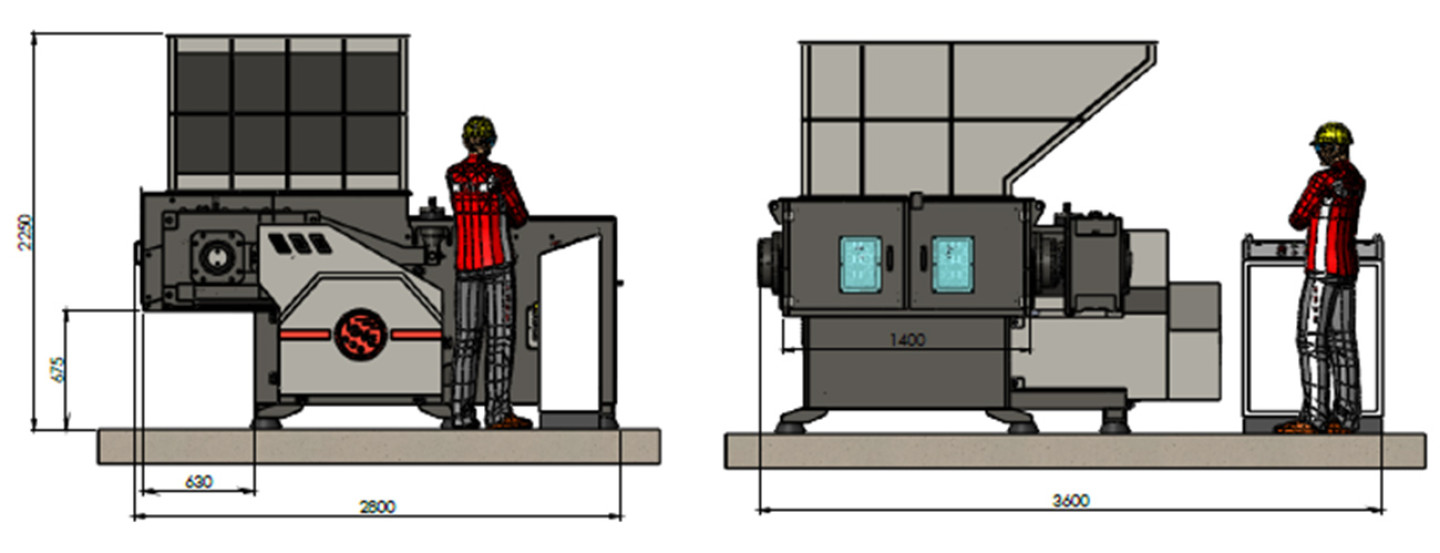

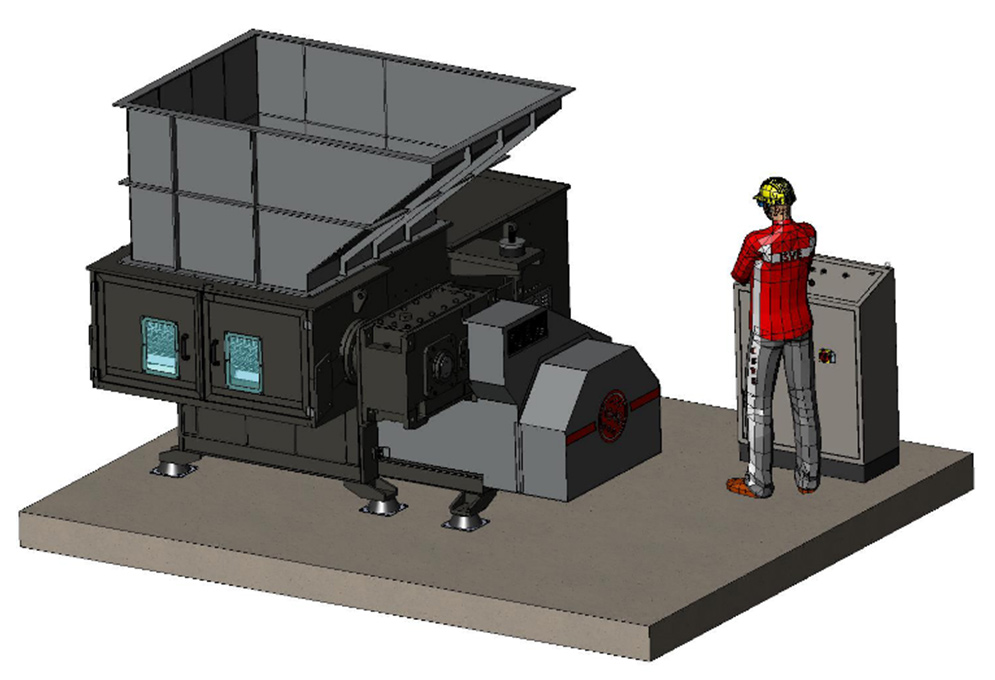

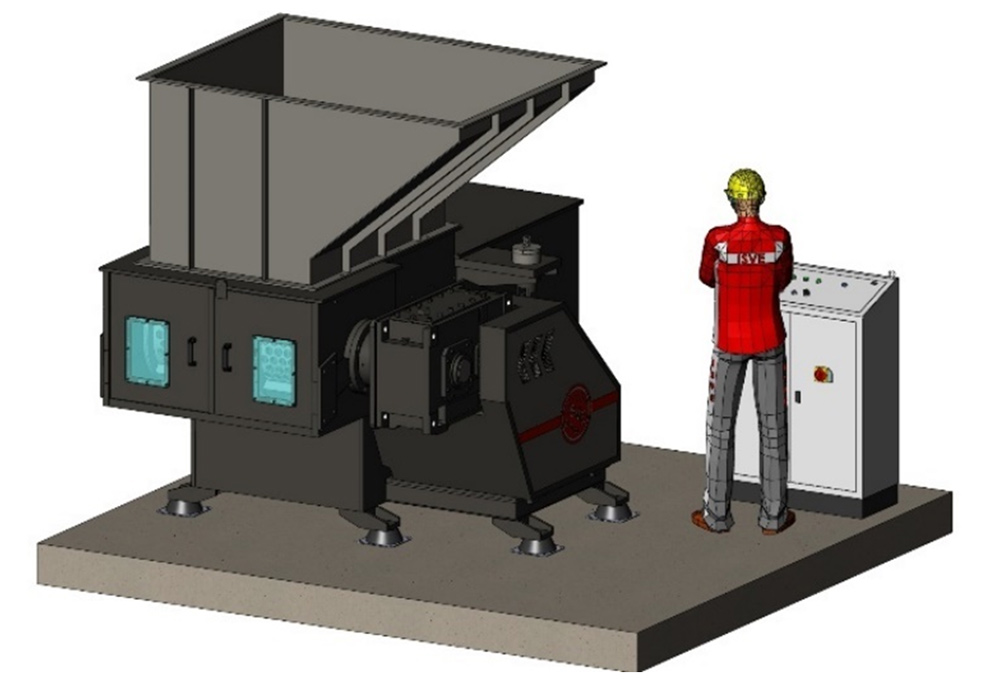

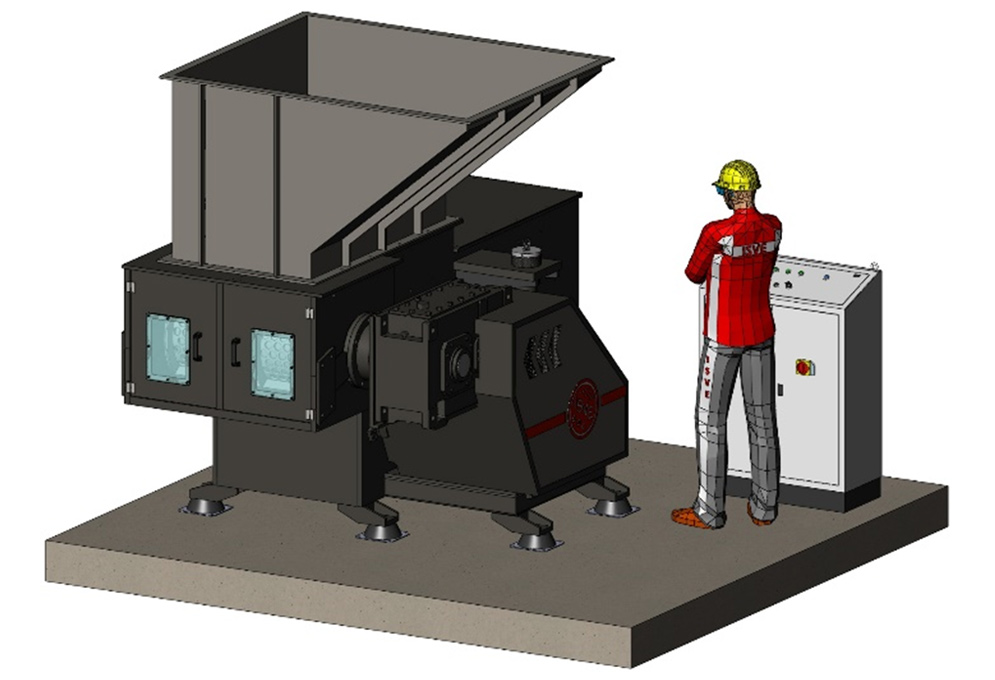

The MR 40-120 singe-shaft equipped shredder is particularly suitable to shred high quantities of industrial wastes.

The MR 40-120 singe-shaft equipped shredder is particularly suitable to shred high quantities of industrial wastes.

Loading unit:

Loading unit: Motor drive:

Motor drive: